Energy-efficient upgrades for commercial and industrial facilities

Commercial and industrial facilities can significantly lower energy consumption and operating costs through targeted upgrades that address lighting, HVAC, motors, controls, and building envelope. Strategic planning that links energy measures to maintenance, procurement, and workforce training improves return on investment and supports sustainability goals across manufacturing, logistics, and supply chain operations.

Energy-efficient upgrades for commercial and industrial facilities

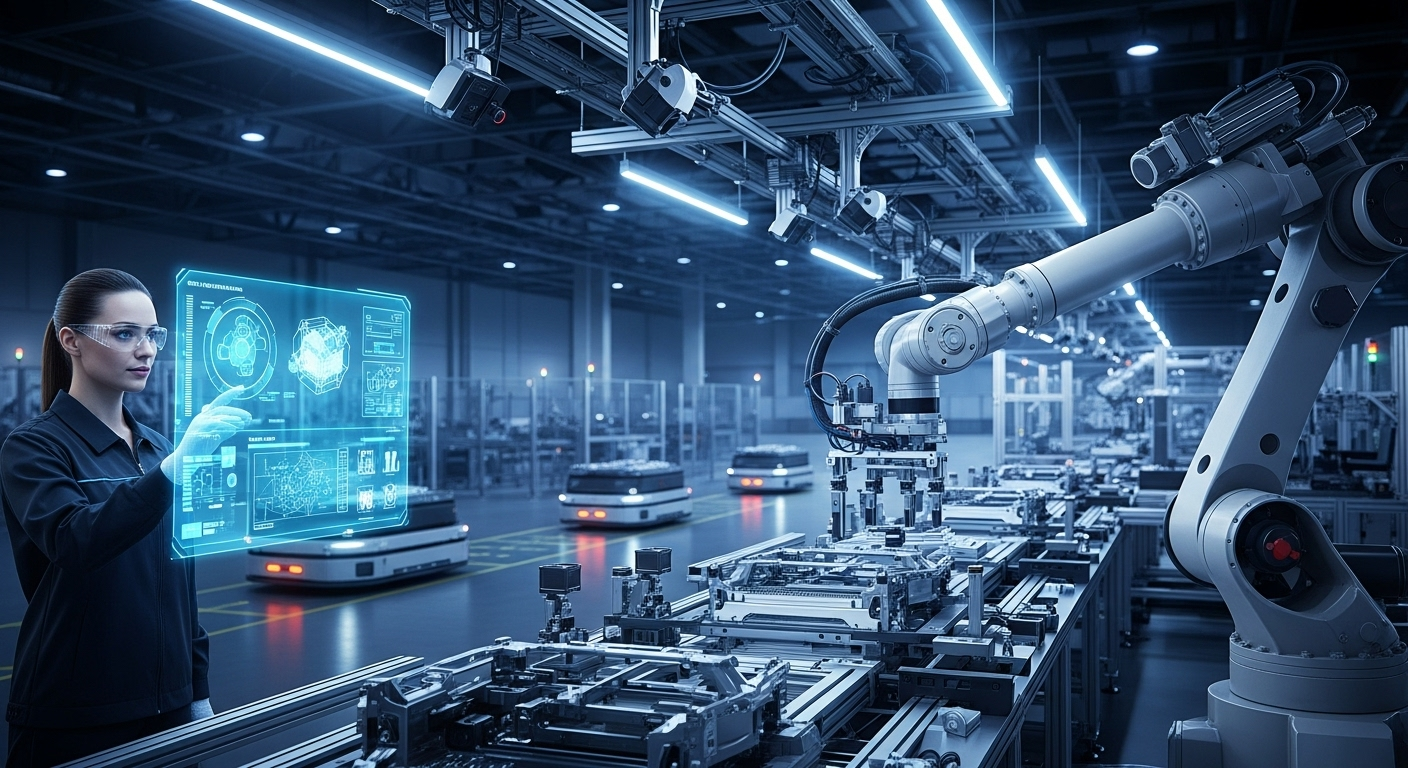

Commercial and industrial sites represent a large share of global energy use, and targeted upgrades can reduce consumption while improving reliability and compliance. Energy-efficiency projects often touch multiple functions — from automation and robotics on production lines to lighting and HVAC in warehouses — so planning should align with maintenance cycles, procurement strategies, and workforce capabilities to ensure measurable gains.

How can manufacturing reduce energy use?

Manufacturing plants benefit from a layered approach: begin with energy audits to identify high-use equipment, then prioritize measures such as high-efficiency motors, variable frequency drives (VFDs), heat recovery, and process optimization. Retro-commissioning older systems often restores lost efficiency and uncovers control opportunities. Integrating robotics and automation can reduce cycle times and idle energy, but must be paired with controls and sensors to avoid shifting energy burdens elsewhere. Aligning upgrades with compliance and safety requirements prevents operational disruptions while improving overall equipment effectiveness.

What upgrades help logistics and warehousing?

Warehouses and distribution centers should focus on lighting retrofits (LEDs with smart controls), HVAC zoning, and dock door insulation to reduce infiltration losses. Refrigerated logistics require careful attention to insulation, compressor optimization, and defrost controls. Building envelope improvements and motion-aware lighting reduce baseline loads, while analytics on occupancy and workflow can drive dynamic setpoint adjustments. Procurement teams can specify energy performance in new racking, conveyors, and handling equipment to ensure lifecycle savings are realized.

How does automation improve energy efficiency?

Automation enables precision control that reduces waste and energy use. Advanced process controls, predictive maintenance algorithms, and robotics coordination reduce unnecessary idling and smoothing of power demand. Energy-aware automation strategies include scheduling energy-intensive tasks during low-tariff periods, implementing soft starts for large motors, and using demand response-compatible controls. Analytics and machine learning can reveal inefficient patterns in production or material handling and recommend targeted interventions that improve throughput and energy intensity metrics.

What role does sustainability play in upgrades?

Sustainability frames upgrades beyond immediate cost savings, incorporating carbon reduction, circularity, and regulatory compliance. Measures such as onsite generation (solar, combined heat and power), electrification of processes, and improved waste-heat capture contribute to emissions targets and may unlock incentives. Integrating sustainability reporting with energy analytics makes it easier to track progress across the supply chain and demonstrate performance to stakeholders. Workforce training and change management are crucial to embed sustainable operational practices and maintain long-term benefits.

How to integrate analytics and cybersecurity?

Energy monitoring and analytics platforms provide visibility into consumption by asset, process, and shift, enabling targeted interventions and continuous improvement. However, digitization increases cybersecurity exposure: ensure segmentation of operational technology networks, enforce patching and access controls, and use encrypted telemetry for remote monitoring. Analytics also support compliance and procurement decisions by quantifying savings, lifecycles, and replacement priorities. Combining data-driven insights with secure implementation preserves both efficiency gains and operational resilience.

How should maintenance and procurement adapt?

Maintenance strategies must evolve from reactive repairs to preventive and predictive models that incorporate energy performance as a KPI. Condition-based monitoring and vibration or thermal sensors can indicate when equipment is consuming more power than expected, prompting timely service. Procurement policies should emphasize lifecycle cost and energy performance specifications for motors, compressors, HVAC units, lighting, and automation equipment. Cross-functional collaboration between maintenance, procurement, and engineering ensures upgrades align with spare-parts strategies, warranty terms, and workforce skills, reducing downtime and sustaining efficiency improvements.

Conclusion

Energy-efficient upgrades for commercial and industrial facilities are most effective when they combine technical measures — motors, controls, lighting, HVAC, and building envelope — with organizational changes in procurement, maintenance, and workforce development. Analytics and secure automation enable continuous optimization, while sustainability goals and compliance considerations help prioritize investments. A coordinated approach ensures upgrades deliver both short-term operational benefits and long-term reductions in energy intensity and emissions.